Tuug bir ah oo tayo sare leh oo leh caabbinta xirashada sare

Soo bandhig

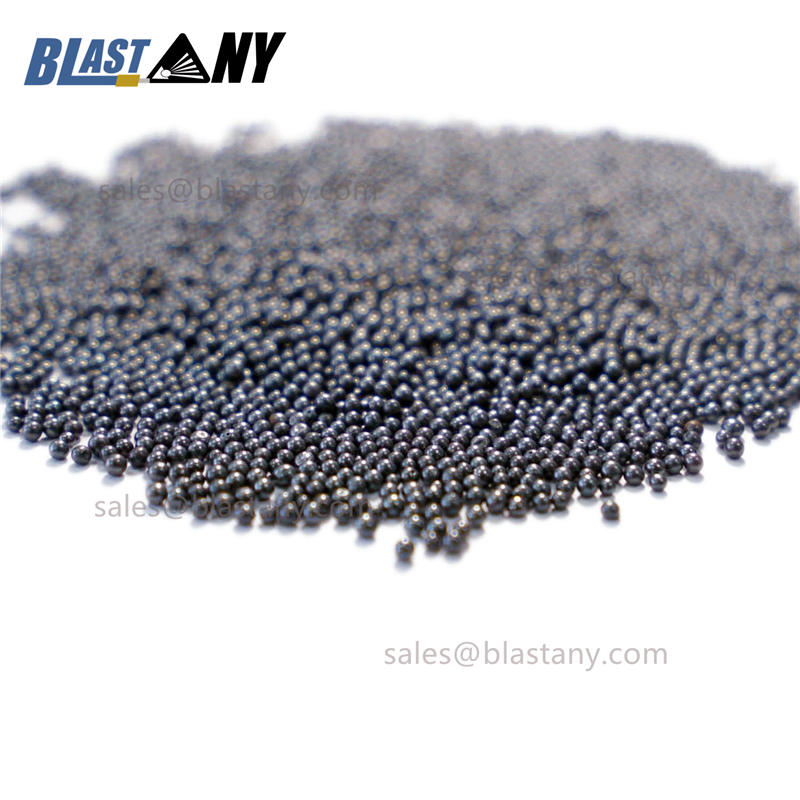

Junda Steel Shot waxaa lagu soo saaray dhalaalidda haraaga la doortay ee foornada korontadu. Halabuurka kiimikada ee birta dhalaalaysa waa la falanqeeyay oo si adag loo xakameeyaa spectrometer si loo helo qeexida heerka SAE. Birta dhalaalaysa waa la atomized oo waxay isu beddeshaa qayb wareeg ah ka dibna la demiyo oo lagu cadhooday habka daawaynta kulaylka si loo helo badeecad adag oo isku mid ah iyo qaab-dhismeed yar, oo lagu eegay cabbir ahaan sida waafaqsan qeexida heerka SAE.

Junda toogashada birta warshaduhu waxay u qaybsantaa afar, tallaal bir ah oo heer qaran ah, oo ka kooban tallaalka birta birta ah ee chromium, kaniiniyada birta kaarboonka hooseeya, birta aan la taaban karin, oo ay ku jiraan tallaalka birta birta ee heerka qaranku waxay si buuxda u waafaqsan tahay shuruudaha heerka qaran ee nuxurka curiyaha ee wax soo saarka, iyo curiyaha chromium tuuray birta birta, waxay ku saleysan tahay heerka qaran ee kubbadaha birta, ku darista ferromanganese ferrochrome ferrochrome geeddi-socod sida Owen Habka wax-soo-saarka birta kaarboonka ee hooseeya iyo tallaalka birta heerka qaranka, laakiin alaabta ceeriin waa birta kaarboon yar, ka kooban kaarboonku wuu hooseeyaa; Toogashada birta ah waxaa lagu soo saaraa atomizing habka samaynta, alaabta ceeriin waa bir ahama, 304, 430 ahama iyo wixii la mid ah.

Noocan ah toogashada waxaa loo sameeyaa si loogu isticmaalo qarxinta rasaasta iyo hababka qarxinta cadaadiska hawo ciriiri ah. Asal ahaan waxaa loo isticmaalaa biraha aan birta ahayn sida aluminium, aluminium zinc, birta aan lahayn, bronze, naxaasta, naxaasta ...

Iyada oo kala duwan oo kala duwan ee darajooyin, waxaa loo isticmaalaa nadiifinta, deburting, cufnaanta, toogashada toogashada iyo hababka dhammayn guud, on dhammaan noocyada kala duwan ee qaybaha, iyada oo aan wasakhayn dusha sare by boodhka ferrous kaas oo sii xumaanaya oo beddela midabka biraha la daweeyay. habka gabowga ee marmar iyo granite.

Codsiga warshadaha

Rasaasta birta ah qarxinta

Xabad bir ah oo nadiifinaysa ciidda tuurista oo gubatay -cad ciid shubka si ay dusha sare u hesho nadaafad wanaagsan iyo qallafsanaan loo baahan yahay, si ay faa'iido ugu yeelato habaynta iyo daahan dambe.

Tuug bir ah oo loogu talagalay diyaarinta saxanka Birta

Toogashada birta ah ayaa nadiifinaysa maqaarka oksaydhka, miridhka iyo wasakhda kale iyada oo la adeegsanayo xabbad-qarxinta, ka dibna isticmaal nadiifiyaha faakuumka ama hawada la safeeyey si aad u nadiifiso dusha alaabta birta ah.

Qalabka birta ah ee loo isticmaalo mishiinada injineernimada

Tallaabooyinka birta ah ee loo isticmaalo nadiifinta mishiinada waxay si wax ku ool ah uga saari karaan miridhku, alxanka alxanka, iyo maqaarka oksaydhka, waxay baabi'in karaan walbahaarka alxanka, waxayna kordhiyaan xoogga aasaasiga ah ee u dhexeeya daahan ka saarista miridhku iyo birta, sidaas darteed waxay si weyn kor ugu qaadaysaa tayada wasakhda ee qayb ka mid ah mishiinnada injineernimada.

Cabbirka toogashada birta ee nadiifinta saxannada birta ah

Si loo gaaro nadiif, iftiin leh, daawaynta dusha sare ee guban ee saxanka birta ah, waa in ay doorataa agabka xoqida ku haboon si looga saaro miisaanka dusha birta ah ee duuban qabow.

Marka loo eego darajooyin kala duwan, dusha sare ee birta aan la taaban karin waxay u baahan tahay inay doorato abrasives dhexroorka kala duwan iyo saamiga habka loo shaqeeyo. Marka la barbardhigo habka kiimikada ee dhaqameed, waxay hoos u dhigi kartaa kharashka nadiifinta waxayna gaari kartaa wax soo saarka cagaaran.

Warbaahin qarax bir ah oo loogu talagalay dhuumaha ka hortagga daxalka

Tuubooyinka birta waxay u baahan yihiin daaweyn dusha sare ah si ay u xoojiyaan caabbinta daxalka. By toogashada birta ah, qarxinta warbaahinta polishes, nadiifiyaa oo ka saartaa oksaydhka iyo lifaaqyada lagu gaaro miridhku codsaday ka saaray darajada iyo qoto dheer hadhuudh ah, ma aha oo kaliya nadiifinta dusha sare laakiin sidoo kale ku qanca adhesion u dhexeeya tuubada birta iyo daahan, gaadho saamaynta anti-daxalka wanaagsan

Xoojinta toogashada birta

Qaybaha birta ah ee ku shaqeeya xaalada rarida baaskiilka oo lagu sameeyay ficilka walaaca baaskiil wadida waxay u baahan yihiin in la toogto habka xoojinta xoojinta si loo hagaajiyo nolosha daalka.

Tuubbada birta ah ee la tuuro Codsiga

birta toogashada toogashada waxaa inta badan loo isticmaalaa in lagu xoojiyo processing ee qaybaha muhiimka ah sida helical guga, guga caleen, bar qalloocan, marsho, qaybaha gudbinta, sita, usheeda dhexe Cam, dhuuban ul, xidha ushii iyo wixii la mid ah. Marka ay diyaaraddu soo degayso, qalabka soo degaya waa in uu u adkaystaa saamaynta ba'an ee ay ugu baahan tahay daawaynta toogta oo joogto ah. Baalashu waxay sidoo kale u baahan yihiin daawaynta sii deynta walaaca xilliyeed.

Qiyaasaha Farsamada

| Mashruuca | Heerarka Qaranka | Tayada | |

| Halabuurka kiimikada% | C | 0.85-1.20 | 0.85-1.0 |

| Si | 0.40-1.20 | 0.70-1.0 | |

| Mn | 0.60-1.20 | 0.75-1.0 | |

| S | <0.05 | <0.030 | |

| P | <0.05 | <0.030 | |

| Adag | xabbad bir ah | HRC40-50 HRC55-62 | HRC44-48 HRC58-62 |

| Cufnaanta | xabbad bir ah | ≥7.20 g/cm3 | 7.4g/cm3 |

| Qaab-dhismeedka yar yar | Martensite xanaaqsan ama Troostite | Xanaaqa Martensite Bainite urur ka kooban | |

| Muuqashada | Goobaysan Qaybaha madhan <10% Qayb dildilaaca <15% | Goobaysan Qaybaha madhan <5% Qayb dildilaac <10% | |

| Nooca | S70, S110, S170, S230, S280, S330, S390, S460, S550, S660, S780 | ||

| Baakad | Tan kasta oo ku jira baaldi gaar ah iyo tan kasta oo loo qaybiyay 25KG xidhmo. | ||

| Waarta | 2500 ~ 2800 jeer | ||

| Cufnaanta | 7.4g/cm3 | ||

| Dhexroorka | 0.2mm, 0.3mm, 0.5mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.4mm, 1.7mm, 2.0mm, 2.5mm | ||

| Codsiyada | 1. Nadiifinta qaraxa: Waxaa loo isticmaalaa nadiifinta qarxinta tuurista, shubista, been-abuurka; ciidda ka saarista shubka, saxan birta, birta nooca H, qaab-dhismeedka birta. 2. Ka saarida miridhku: Ka saarista miridhku ee shubka, been-abuurka, saxan birta, H nooca steel, qaab-dhismeedka birta. 3. Toosinta toogashada: Toogtay qalabka, qaybaha kulaylka lagu daweeyay. 4. Shot qarxinta: Shot qarxinta birta profile, guddiga markabka, guddiga birta, walxaha birta, qaab-dhismeedka birta. 5. Daawaynta ka hor: Kahor daawayn dusha sare ah, guddiga birta, birta profile, qaab dhismeedka birta, ka hor inta aan rinjiyeyn ama dahaarka. | ||

Baaxadda Qaybinta Birta Xabadda

| SAE J444 Standard Steel shot | Shaashada No. | In | Cabbirka shaashadda | |||||||||||

| S930 | S780 | S660 | S550 | S460 | S390 | S330 | S280 | S230 | S170 | S110 | S70 | |||

| DHAMMAAN dhaaf | 6 | 0.132 | 3.35 | |||||||||||

| Dhammaan Gudub | 7 | 0.111 | 2.8 | |||||||||||

| 90% min | Dhammaan Gudub | 8 | 0.0937 | 2.36 | ||||||||||

| 97% min | 85% min | Dhammaan Gudub | Dhammaan Gudub | 10 | 0.0787 | 2 | ||||||||

| 97% min | 85% min | 5% ugu badnaan | Dhammaan Gudub | 12 | 0.0661 | 1.7 | ||||||||

| 97% min | 85% min | 5% ugu badnaan | Dhammaan Gudub | 14 | 0.0555 | 1.4 | ||||||||

| 97% min | 85% min | 5% ugu badnaan | Dhammaan Gudub | 16 | 0.0469 | 1.18 | ||||||||

| 96% min | 85% min | 5% ugu badnaan | Dhammaan Gudub | 18 | 0.0394 | 1 | ||||||||

| 96% min | 85% min | 10% ugu badnaan | Dhammaan Gudub | 20 | 0.0331 | 0.85 | ||||||||

| 96% min | 85% min | 10% ugu badnaan | 25 | 0.028 | 0.71 | |||||||||

| 96% min | 85% min | Dhammaan Gudub | 30 | 0.023 | 0.6 | |||||||||

| 97% min | 10% ugu badnaan | 35 | 0.0197 | 0.5 | ||||||||||

| 85% min | Dhammaan Gudub | 40 | 0.0165 | 0.425 | ||||||||||

| 97% min | 10% ugu badnaan | 45 | 0.0138 | 0.355 | ||||||||||

| 85% min | 50 | 0.0117 | 0.3 | |||||||||||

| 90% min | 85% min | 80 | 0.007 | 0.18 | ||||||||||

| 90% min | 120 | 0.0049 | 0.125 | |||||||||||

| 200 | 0.0029 | 0.075 | ||||||||||||

| 2.8 | 2.5 | 2 | 1.7 | 1.4 | 1.2 | 1 | 0.8 | 0.6 | 0.4 | 0.3 | 0.2 | GB | ||

Tallaabooyinka wax soo saarka

Wax cayriin

Samaynta

Qalajinta

Baaritaanka

Xulashada

xanaaqsan

Baaritaanka

Xidhmada

Qaybaha alaabta