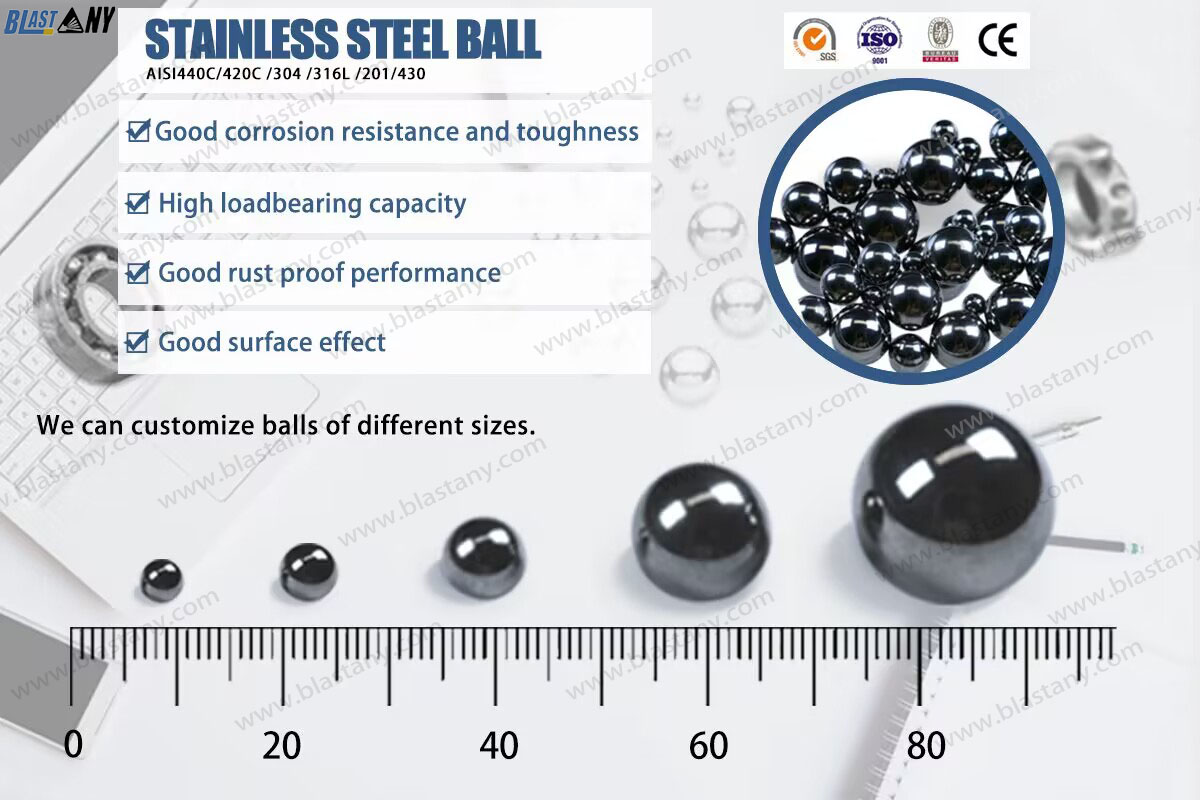

Sahayda warshadda 0.35mm- 50.8mm HRC50-55 iftiinka AISI304 316 430 440 Kubadda birta ah ee loo isticmaalo

Sharaxaada badeecada

Kubadaha aan nadiifka ahayn waxay awood u leeyihiin inay iska caabiyaan daxalka wakiilada sida xalalka oksaydhaynta, kiimikooyinka organic intooda badan, walxaha cuntada iyo xalalka nadiifinta. Waxay si dhexdhexaad ah u adkaysanayaan asiidhyada sulfuric. Guryaha aan magnetka ahayn ayaa la heli karaa marka la codsado. Codsiyada waxaa ka mid ah aerosol-ka, buufiyeyaasha, hababka matoorka faraha, isku-dhafka mashiinka caanaha, qalabka wax lagu sameeyo iyo codsiyada caafimaadka.

AISI 440C Kubadda birta ah ee aan lahayn

Cabbirka: 0.35mm-50.8mm

Fasalka: G10, G16, G40, G60, G100, G200.

Adag: HRC56-58,Hartford 440C Kubadaha birta ah ee aan fiicnayn ayaa loo oggolaaday inay ka saaraan wasakhowga birta ee bilaashka ah una fududeeyaan samaynta iskiis u samaysan ee filim ilaalin ah.

Magnetic: Birta Martensitic, Magnetic

Astaamaha: saxnaanta sare, iska caabbinta daxalka wanaagsan, miridhku xooggan iyo iska caabinta xidhashada.

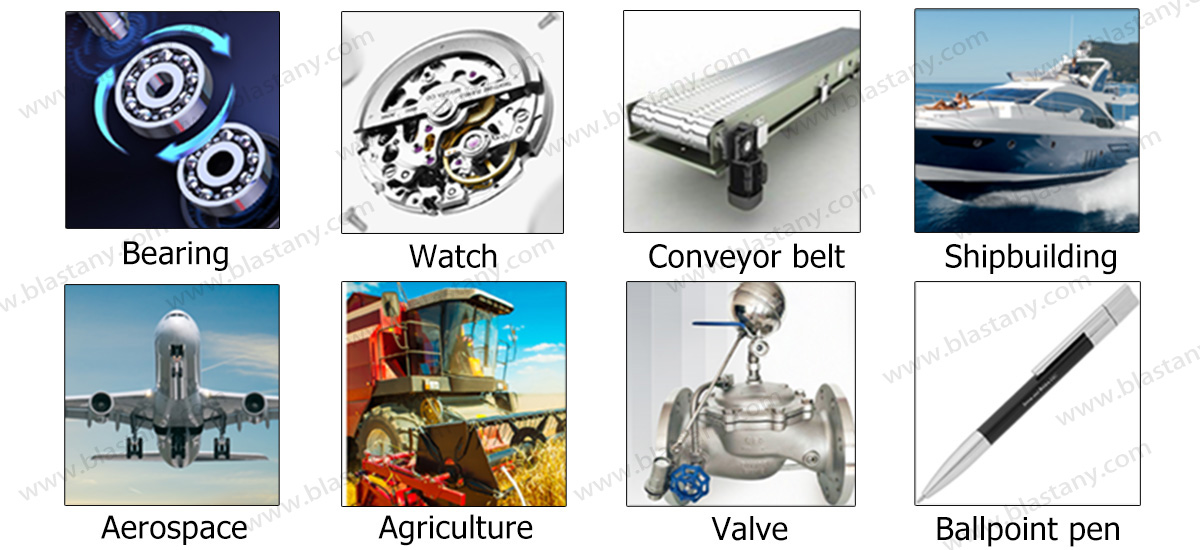

Codsiyada: Gawaarida, Shaabadaynta, Qaybaha Haydarooliga, valves, Aerospace, Shaabadadaha, Qalabka Qaboojiyaha, Qalabka Saxda ah ee Sare, iwm.

| Halabuurka kiimikada | ||||||||

| AISI 440C | C | Si | Mn | P | S | Ni | Cr | Mo |

| 0.95-1.10 | ≤0.80 | ≤0.80 | ≤0.04 | ≤0.03 | ≤0.60 | 16.0-18.0 | 0.75 | |

AISI 420C Kubadda birta ah ee aan lahayn

Cabbirka: 0.35mm-50.8mm

Fasalka: G10-G1000

Adag: HRC50-55

Magnetic: Birta Martensitic, Magnetic,Awoodda ka hortagga miridhku fiican,Adayg sare,AISI 420 kubbadaha birta aan fiicnayn waxay muujinayaan sifooyin xidhasho wanaagsan iyo adayg. In yar oo adkeysi ka yar iyo iska caabin daxalka weyn, marka la barbar dhigo 440C.

Sifooyin: Caadi ahaan loo yaqaan birta aan-ka-tooska lahayn, caabbinta daxalka wanaagsan iyo adkaanta

Codsiyada:Dhammaan noocyada kala duwan ee mashiinada saxda ah, biraha, qalabka korontada, qalabka guriga, qaybaha baabuurta, iwm.

| AISI 420C (4Cr13) | C | Si | Mn | P | S | Ni | Cr | Mo |

| 0.36-0.43 | ≤0.80 | ≤1.25 | ≤0.035 | ≤0.03 | ≤0.60 | 12.0-14.0 | ≤0.60 |

430 kubad bir ah

Dhexroorka: 1MM-50.80MM

Adag: HRC26

Fasalka: G10-G1000

Astaamaha: qiimo jaban, iska caabin miridhku liito.

Codsiga: qalabka, qurxinta, accessories, qurxinta, warshadaha, warshadaha leh shuruudaha hoose ee waxqabadka lidka ku ah. iyo kubbadaha valve.

| AISI 430 | C | Si | Mn | P | S | Ni | Cr | Mo |

| ≤0.12 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | - | 16.0-18.0 | - |

AISI 304 Kubadda birta ah ee birta ah

Cabbirka: 0.5mm-63.5mm

Darajada: G80-G500

Adag: ≤HRC21

Magnetic: birta Austenitic, non-magnetic

Features: iska caabin miridhku xoog, caabin daxalka wanaagsan.widely loo isticmaalo, waxqabadka caddayn miridhku wanaagsan, saamaynta dusha wanaagsan, shahaado ilaalinta deegaanka.

Codsiyada: Qalabka guriga sida valves, dhalooyinka cadarka, cidiya, dhalada dhallaanka, qaybaha baabuurta, qaboojiyaha, qalabka korantada, waxyaalaha la isku qurxiyo, slide sita, qalabka caafimaadka, dahabka iyo warshado kale oo badan.

| Halabuurka kiimikada | |||||||

| AISI 304 | C | Si | Mn | P | S | Ni | Cr |

| ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.0-10.5 | 18.0-22.0 | |

AISI 316L Kubadda birta ah ee aan lahayn

Cabbirka: 1.0mm-63.5mm

Darajada: G80-G500

Adag: ≤HRC26

Magnetic: birta Austenitic, non-magnetic

Astaamaha: kuwa ugu habboon warshadaha leh shuruudaha sare ee ka-hortagga daxalka, iyo awoodda ka-hortagga miridhku waa mid aad u xoog badan, iska caabin heer sare ah u leh daxalka (marka laga reebo acids chloridric), Austenitic inox aan la adkeyn karin

Codsiyada: AISI 316L kubbadda birta ah ee birta ah waxaa loo isticmaali karaa qalabka caafimaadka, warshadaha kiimikada, duulista, hawada, qalabka caaga ah, dhalada cadarka, buufiyo, valves, Polish ciddiyaha, motor, beddelo, birta, mishiinada dharka, qaboojiyaha, qaboojiyaha, alaabta dawooyinka, qaybo auto, biraha, qalab, dhalada.

AISI 316L Kubadda birta ah ee aan lahayn

| Halabuurka kiimikada | ||||||||

| AISI 316L | C | Si | Mn | P | S | Ni | Cr | Mo |

| ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 12.0-15.0 | 16.0-18.0 | 2.0-3.0 | |

Baakadaha alaabta

A) Xirmooyinka gudaha: Xirmooyinka saliidda baakadaha qalalan waxaa lagu bixiyaa hadba sida aad u baahan tahay.

B) Baakadaha dibadda:

1) durbaan bir + alwaax / alwaaxdii birta.

2) 25kg bac poly + kartoon + alwaax alwaax ah ama sanduuq alwaax ah.

baakad gaar ah.

Halbeegga Alaabta

| Kubbadeena Birta Aan-la-aanta ah waxaa ku jira 440C 420C 304 316 201, Halabuurka Kiimikada waa sida soo socota | |||||||||

| Halabuurka kiimikada (%) | C | Cr | Si | Mn | P | S | Mo | Ni | Cu |

| AISI440C SS Ball | 0.95-1.2 | 16-18 | ≤0.80 | ≤0.80 | ≤0.04 | ≤0.03 | ≤0.75 | ≤0.6 | ---- |

| AISI420C SS Ball | 0.26-0.43 | 12-14 | ≤0.80 | ≤1.25 | ≤0.035 | ≤0.03 | ≤0.6 | ≤0.6 | ---- |

| AISI304 SS Ball | ≤0.08 | 18-22 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | ---- | 8-10 | ---- |

| AISI316L SS Ball | ≤0.08 | 16-18 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 2.0-3.0 | 12-15 | ---- |

| AISI201 SS Ball | ≤0.15 | 16-18 | ≤1.0 | 5.5-7.5 | ≤0.045 | ≤0.03 | ---- | 0.35-0.55 | 1.82 |

| AISI430 SS Ball | ≤0.12 | 16-18 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | ---- | ---- | ---- |

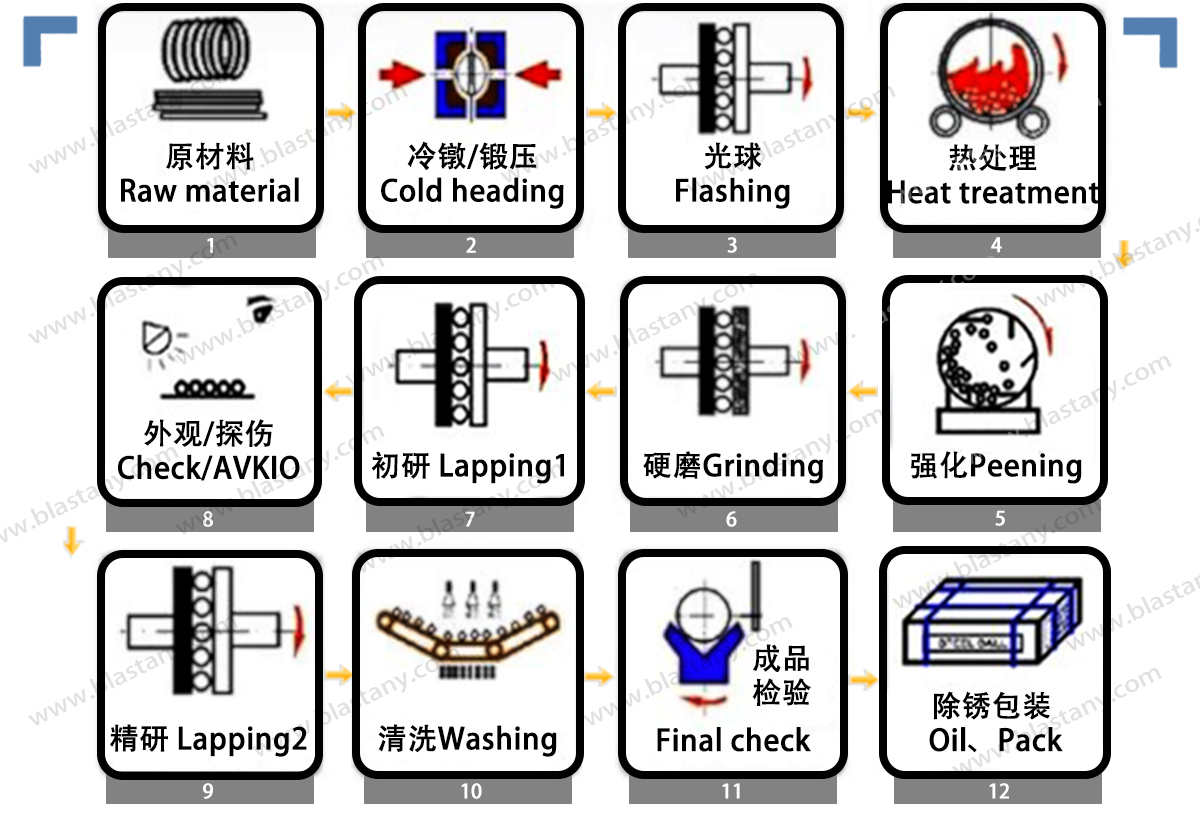

Socodka wax soo saarka

Kormeerka Qalabka Ceyriinka

Walxaha ceeriin waxay ku yimaadaan qaab silig. Marka hore, alaabta ceeriin waxaa si muuqaal ah u eegaya kormeerayaasha tayada si ay u go'aamiyaan haddii tayada ay ku xiran tahay calaamadda iyo haddii ay jiraan waxyaabo cilladaysan. Marka labaad, hubi dhexroorka oo dib u eeg shahaadooyinka alaabta ceeriin.

Ciwaanka Qabow

Mashiinka ciwaanka qabowgu wuxuu gooyaa dherer go'an oo walxaha siliga ah oo u gooya slugs cylindrical ah. Intaa ka dib, labada geesood ee ciwaanka ah ee ciwaanka ah ayaa dhinta waxa ay ka dhigtaan slug qaab wareegsan. Habkan been abuurka ah waxaa lagu sameeyaa heerkulka qolka iyo qadar yar oo ah walxo lagu daro ayaa la isticmaalaa si loo hubiyo in godka dhinta si buuxda loo buuxiyo. Ciwaanka qabow waxa lagu sameeyaa xawli aad u sarreeya, celceliska xawaaraha hal kubad weyn ilbiriqsikii. Kubadaha yaryar waxa ay ku socdaan xawaare dhan laba ilaa afar kubbadood ilbiriqsikiiba.

Biligleynaya

Inta lagu jiro habkan, walxaha xad-dhaafka ah ee lagu sameeyay kubbadda ayaa go'i doona. Kubadaha waxa la dhaafaa dhawr jeer inta u dhaxaysa laba saxan oo kabka ah oo jeexjeexan oo ka saaraya xaddi yar oo alaabta dheeraadka ah marka ay duuban yihiin.

Daawaynta kulaylka

Qaybaha ayaa markaa loo malaynayaa in lagu daaweeyaa kulaylka iyadoo la isticmaalayo hababka dab-deminta iyo heerkulka. Ka dib daaweynta kulaylka bilowga ah, qaybaha waxaa lagu rusheeyaa kaydka saliidda. Qaboojintan degdega ah (saliida deminta) waxay soo saartaa martensite, weji bir ah oo lagu garto qallafsanaan sare iyo sifooyin xidhid sare. Hawlgallada xamaasadda ee xiga waxay sii yareynayaan walbahaarka gudaha ilaa laga gaaro xadka ugu dambeeya ee adag ee la cayimay.

shiidid

Shiididda waxaa la sameeyaa ka hor iyo ka dib daaweynta kulaylka. Dhamaystir shiididda (sidoo kale loo yaqaan Shiidin adag) waxay kubbadda u soo dhawaataa shuruudaheeda kama dambaysta ah.Heerka kubbadda birta ee saxda ahwaa cabbir lagu cabbiro saxnaanta guud; Tirada hoose, inta saxda ah waa kubada. Darajada kubbadu waxay ka kooban tahay dulqaadka dhexroorka, wareegsanaanta (sphericity) iyo qallafsanaanta dusha sare oo sidoo kale loo yaqaan dhammaystirka dusha sare. Soo saarista kubbadda saxda ah waa hawlgal dufcad ah. Cabbirka Lot waxaa lagu go'aamiyaa cabbirka mishiinnada loo isticmaalo shiididda iyo hawl-qabadka.

Dhabarka

Dhabarashadu waxay la mid tahay shiidid laakiin waxay leedahay heer ka saarista walxaha si aad ah uga hooseeya. Dhabarka waxaa lagu sameeyaa iyadoo la isticmaalayo laba taarikada phenolic iyo slurry aad u fiican sida boodhka dheemanka. Habkan wax soo saarka ugu dambeeya wuxuu si weyn u wanaajiyaa qallafsanaanta dusha sare. Dhabarka waxaa loo sameeyaa darajooyinka kubbadda saxda ah ee sare ama saxnaanta sare.

Nadiifinta

Hawlgalka nadiifinta ayaa markaa ka saaraya dareere kasta oo farsameeya iyo walxaha haraaga ah ee habka wax soo saarka. Macaamiisha waydiisa shuruudaha nadiifinta adag, sida kuwa ku jira mikroelectronics, caafimaadka ama warshadaha cuntada, waxay ka faa'iidaysan karaan Hartford Technologies doorashooyin nadiifin oo casri ah.

Kormeerka Muuqaalka

Ka dib habka wax soo saarka aasaasiga ah, mid kasta oo kubbadaha birta ah ee saxda ah waxa la mariyaa hubinta tayada tayada ee hab-socodka. Kormeer muuqaal ah ayaa la sameeyaa si loo hubiyo cilladaha sida miridhka ama wasakhda.

Roller Gauging

Qiyaasta rullaluistu waa 100% habsocod kala soocida taas oo kala saarta kubbadaha birta ee cabbirkoodu hooseeyo iyo kuwa ka weynba. Fadlan kala eeg annagaFiidiyow ku saabsan habka cabbiraadda rullaluistuyada.

Xakamaynta tayada

Kubbado badan oo kasta oo sax ah ayaa la kormeeraa si loo hubiyo shuruudaha fasalka ee dulqaadka dhexroorka, wareega iyo qallafsanaanta dusha sare. Inta lagu jiro nidaamkan, sifooyinka kale ee khuseeya sida qallafsanaanta, iyo wixii shuruudo muuqaal ah ayaa sidoo kale la qiimeeyaa.

Qaybaha alaabta