AISI1010/1015/1085 Sare/Kubad kaarboon ah oo hooseeya 0.8 mm - 50.8 mm kubbadda birta kaarboon ee silsiladda silsiladda

Sharaxaada badeecada

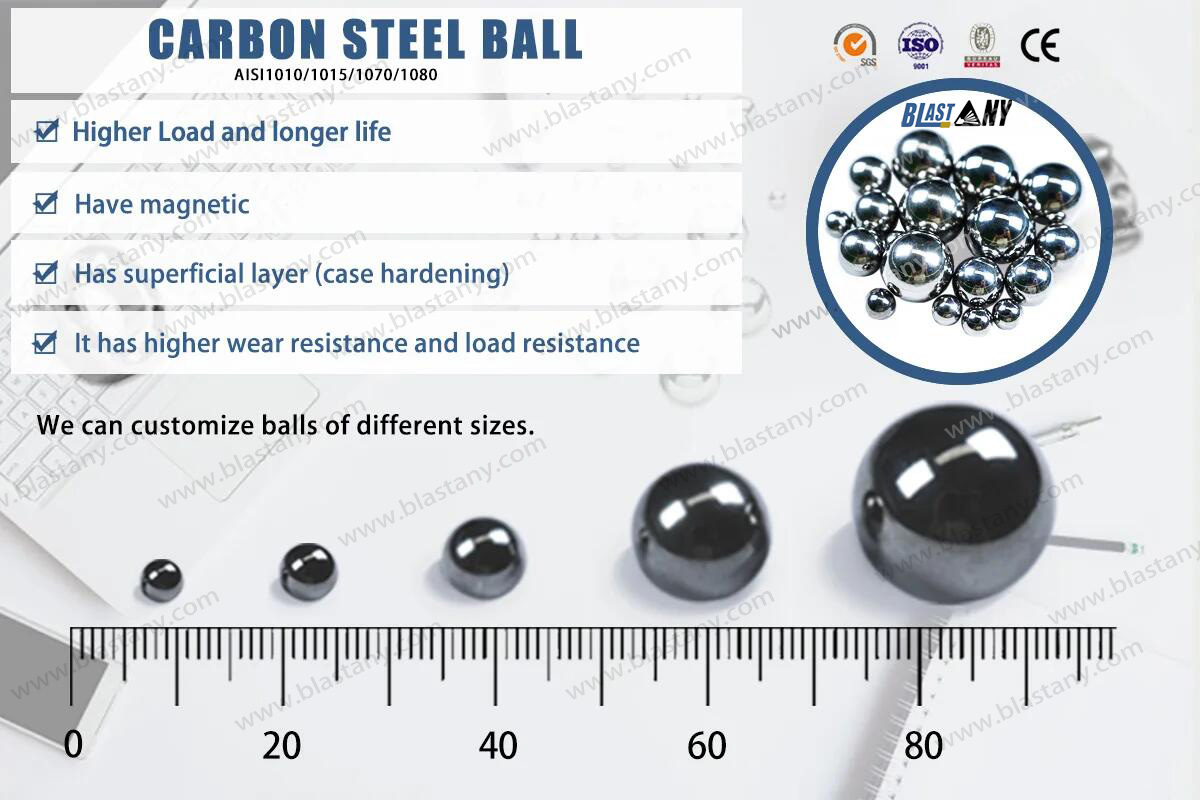

Kubbada Birta Kaarboon-hoosaadka.

| Qalab | AISI1010/1015 |

| Baaxadda cabbirka | 0.8mm-50.8mm |

| Darajo | G100-G1000 |

| Adag | HRC:55-65 |

Sharaxaada Alaabta

Sifooyinka:

Kubadaha birta kaarboon waxay leeyihiin lakab sare (xaalad adag), halka qaybta gudaha ee kubbadu ay ahaanayso qaab-dhismeedka birta ah ee jilicsan waa ferrite, xirmo badiyaa saliid leh. Caadiyan koronto-sameynta marka ay ka baxdo dusha sare , waxaa lagu dhejin karaa zinc , dahab , nikkel , chrome iyo wixii la mid ah . Isbarbardhigga: xidhashada-iska-caabbinta iyo adayggu kama fiicna qaadashada kubbadda birta ( HRC ee kubbadda birta ee GCr15 waa 60-66 ) : markaa , noloshu waa ka gaaban tahay .

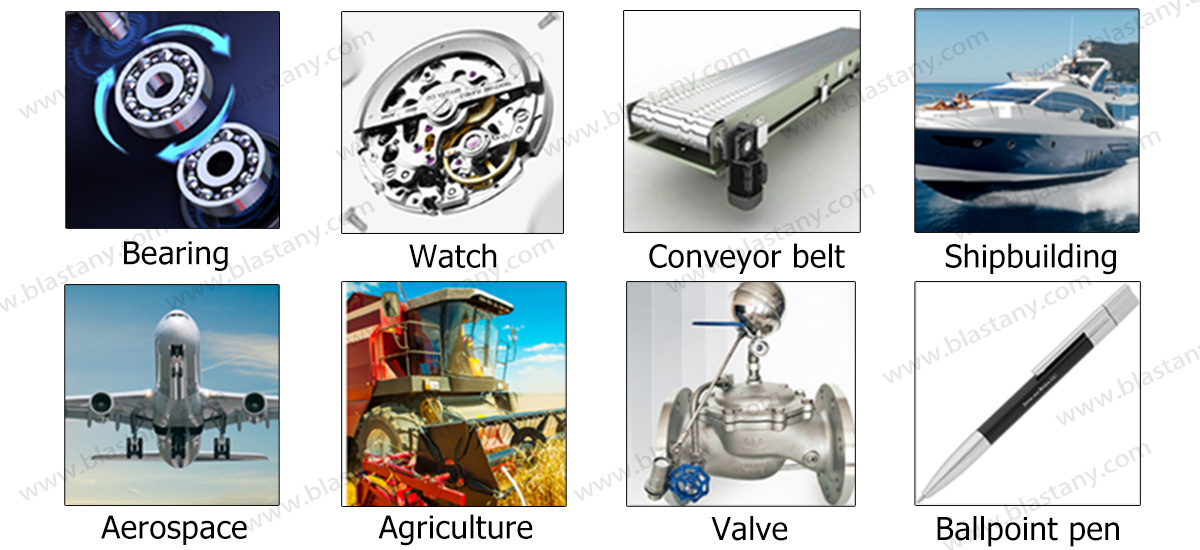

Codsiga:

1010/1015 kubbadda birta kaarboon waa kubbad bir caadi ah, waxay leedahay qiimo jaban, saxsanaan sare iyo isticmaal ballaaran. Waxaa loo istcimaali karaa baaskiilka, xajmiyada, wheel wheel, farsamada gacanta, shelf, kubbada badan, bacaha, qalab yar, waxa kale oo loo isticmaali karaa in lagu xoqo meel-dhexaad kale.

| NOOCA AALADAHA | C | Si | Mn | P (MAX.) | S (MAX.) |

| AISI 1010 (C10) | 0.08-0.13 | 0.10-0.35 | 0.30-0.60 | 0.04 | 0.05 |

| AISI 1015 (C15) | 0.12-0.18 | 0.10-0.35 | 0.30-0.60 | 0.04 | 0.05 |

Kubadda Birta Kaarboonka Sare

| Qalab | AISI1085 |

| Baaxadda cabbirka | 2mm-25.4mm |

| Darajo | G100-G1000 |

| Adag | HRC 50-60 |

Sharaxaada Alaabta

Sifooyinka:

AISI1070/1080 Kubadaha Birta Kaarboon, & Kubadaha birta kaarboonka sarreeya waxay leeyihiin faa'iidooyin cajiib ah marka loo eego tusmada adagaanta oo dhan, taas oo ku saabsan 60/62 HRC waxayna siisaa xirid sare iyo caabbinta culeyska marka loo eego kubbadaha birta adag ee kaarboon hoose ee caadiga ah.

(1) Xuddun adag

(2) Iska caabin hoose oo ka dhanka ah weerarka daxalka ah

(3) Load ka sarreeya iyo nolol ka dheer kubbadda birta kaarboon ee hooseeya

Codsiga:

Qalabka baaskiilka, alaabta guriga lagu xidho kubbadda, hagayaasha silbadhka, suumanka wax qaada, taayirrada rarka culus, qaybaha taageerada kubbadda. Gawaarida saxda ah ee hooseeya, baaskiilka & qaybaha baabuurta, kiciyayaasha, iskeetka, mishiinada dhalaalaysa iyo mishiinada wax lagu shiido,Xirmooyinka saxda ah ee hooseeya.

| NOOCA AALADAHA | C | Si | Mn | P (MAX.) | S (MAX.) |

| AISI 1070 (C70) | 0.65-0.70 | 0.10-0.30 | 0.60-0.90 | 0.04 | 0.05 |

| AISI 1085 (C85) | 0.80-0.94 | 0.10-0.30 | 0.70-1.00 | 0.04 | 0.05 |

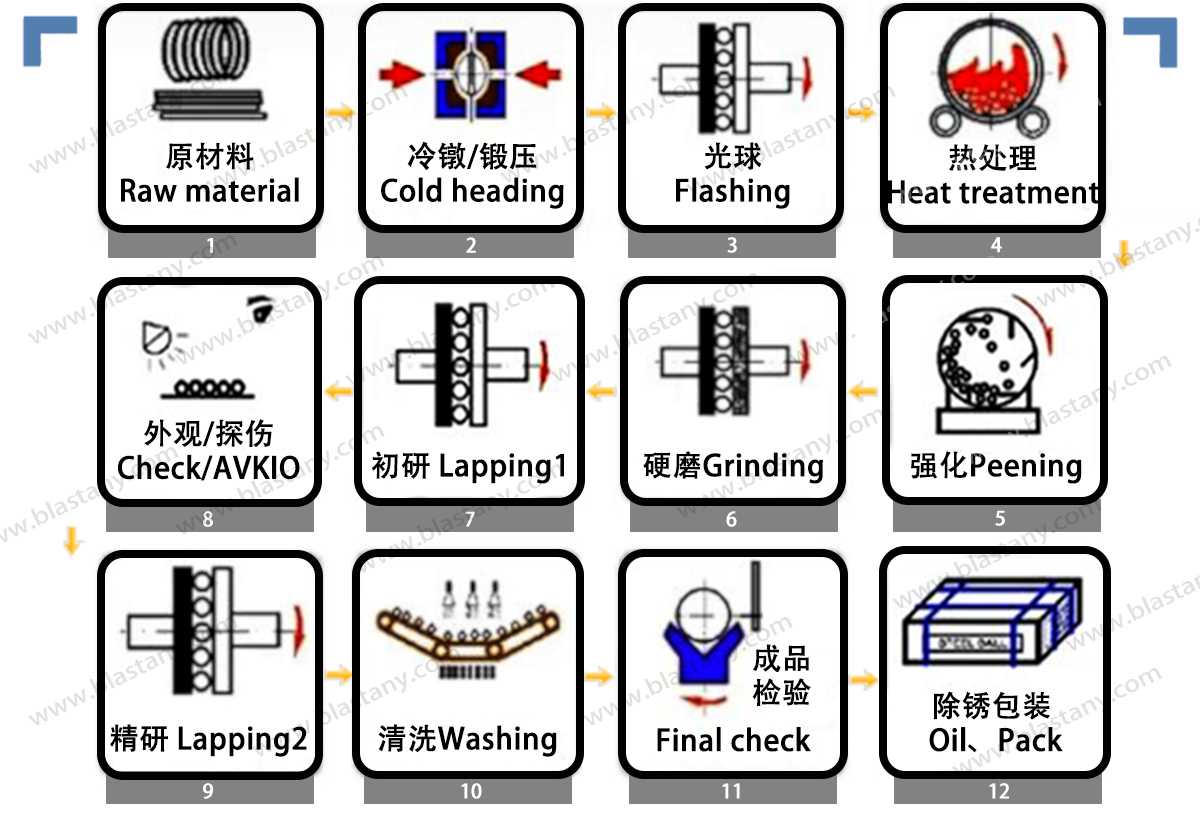

Habka wax soo saarka

Habka Wax-soo-saarka ee Alaabta Kubbada Saxda ah

1.Qalabka Sharciga

Marxaladaha bilowga ah, kubaddu waxay ku bilaabataa qaab silig ama ul. Xakamaynta tayada waxay martaa tijaabada birta si loo hubiyo in ka kooban walxaha la aqbali karo ku dhex jiro.

2.ciwaanka

Ka dib markii alaabta ceeriin ay dhaafto baaritaanka, ka dib waxaa lagu quudiyaa madax xawaare sare leh. Tani waxay samaysaa kubbado qalafsan.

3.Biiqid

Habka biligleynaya wuxuu nadiifiyaa kubbadaha madaxa si ay muuqaal ahaan u siman yihiin.

4.Daawaynta kulaylka

Nidaam heerkul aad u sarreeya oo kubbadaha biligleynaya la dhigo foornada warshadaha. Tani waxay adkeyneysaa kubada.

5.Shiidida

Kubaddu waxay dhulka ku fadhidaa dhexroorka ugu dhow ee cabbirka kubbadda ugu dambeysa.

6.dhabaynta

Laabashada kubbadu waxay keenaysaa cabbirka ugu dambeeya ee la rabo. Tani waa habka ugu dambeeya ee samaynta waxayna ku helaysaa kubbadda heerka dulqaadka.

7.Kormeerkii Ugu Dambeeyay

Kubbada si sax ah ayaa loo cabbiraa waxaana lagu eegayaa Xakamaynta Tayada si loo hubiyo tayada ugu sareysa.

Qaybaha alaabta